In recent years, Europe has witnessed a significant shift in its manufacturing landscape with the advent of Industry 4.0. This fourth industrial revolution, characterized by integrating advanced digital technologies into traditional manufacturing processes, has paved the way for a new era of efficiency, productivity, and innovation. Across the continent, production plants are embracing digital transformation to stay competitive in a rapidly evolving global market. This article will explore how European production plants leverage Industry 4.0 to revolutionize their operations and drive industrial progress.

Internet of Things (IoT) and Connectivity

At the heart of Industry 4.0 lies the Internet of Things (IoT), enabling seamless connectivity and communication of devices and systems. European production plants are harnessing the power of IoT to create smart factories where machines, equipment, and sensors are interconnected. Plant managers can optimize production processes, detect inefficiencies, and predict maintenance needs through real-time data collection and analysis. IoT-enabled systems provide valuable insights, allowing for agile decision-making and improved overall operational efficiency.

Big Data Analytics and Artificial Intelligence (AI)

The abundance of data generated by interconnected devices in production plants has given rise to the application of big data analytics and artificial intelligence. By analyzing vast amounts of data, AI algorithms can identify patterns, predict outcomes, and optimize production parameters. European production plants leverage AI to enhance quality control, minimize defects, and streamline supply chain management. Furthermore, AI-powered robotics and autonomous systems are increasingly integrated into production lines, improving accuracy, speed, and flexibility.

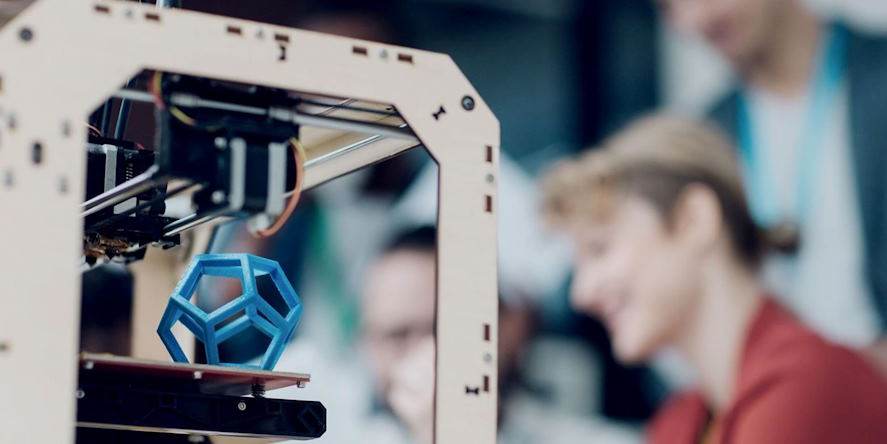

Additive Manufacturing and 3D Printing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production process in Europe’s manufacturing plants. This technology allows for creating complex and customized parts directly from digital designs, reducing material waste and enabling rapid prototyping. European production plants are harnessing the potential of 3D printing to enhance product development, shorten lead times, and reduce costs. From automotive components to aerospace parts and medical devices, additive manufacturing drives innovation across various industries.

Robotics and Automation

Robots have long been a staple in production plants, but with Industry 4.0, their capabilities have expanded significantly. European production plants are adopting advanced robotic systems that are collaborative, adaptable, and intelligent. These robots work alongside human workers, taking on repetitive and physically demanding tasks, while humans focus on more complex and creative activities. Robotic automation improves efficiency, quality, and safety, leading to increased productivity and reduced time to market.

Cybersecurity and Data Protection

As production plants become more connected and digitized, ensuring the security of data and systems becomes paramount. European production plants invest in robust cybersecurity measures to protect sensitive information and intellectual property. From implementing encryption protocols and firewalls to training employees on cyber awareness, these plants proactively address the risks associated with digital transformation. Data protection regulations, such as the European Union’s General Data Protection Regulation (GDPR), further reinforce the importance of safeguarding data in the era of Industry 4.0.

Our team of professionals specializes in developing tailored strategies and implementing effective solutions to streamline your business operations and enhance factory production. We believe that a well-organized and optimized workflow is the foundation for achieving operational excellence and improving overall productivity.

Our team of professionals specializes in developing tailored strategies and implementing effective solutions to streamline your business operations and enhance factory production. We believe that a well-organized and optimized workflow is the foundation for achieving operational excellence and improving overall productivity.